40 making a dc motor

A DC motor is an electromechanical energy conversion device, which converts electrical energy input into the mechanical energy output. The operation of the DC motor is based on the principle that when a current carrying conductor is placed in a magnetic field, a mechanical force acts on the conductor. The magnitude of the force is given by, The brushed DC electric motor generates torque directly from DC power supplied to the motor by using internal commutation, stationary magnets (permanent or electromagnets), and rotating electromagnets.. Advantages of a brushed DC motor include low initial cost, high reliability, and simple control of motor speed. Disadvantages are high maintenance and low life-span for high …

After making connections, the motor will rotate. Project 2: Here, we will discuss the connection of a DC Gear motor with the Arduino board using the L293D H-Bridge motor driver. Let's discuss the need to use the L293D H-Bridge motor driver with the DC motor. L293 is defined as the motor driver IC that permits the DC motor to drive in any ...

Making a dc motor

A DC motor field coil is a non-moving part on which winding is wound to produce a magnetic field. This electro-magnet has a cylindrical cavity between its poles. Commutator and Brushes Commutator The commutator of a DC motor is a cylindrical structure that is made of copper segments stacked together but insulated from each other using mica. A brushed DC electric motor is an internally commutated electric motor designed to be run from a direct current power source. Brushed motors were the first commercially important application of electric power to driving mechanical energy, and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. The very simplest DC electric motors work by placing an electromagnet in a magnetic field made by a permanent magnet. The electromagnet is a piece of iron or steel with wire wound around it in one direction, and it turns the drive shaft which can spin freely along one axis.

Making a dc motor. How to Make a DC Motor at Home (Cardboard DC Motor)Today I'll show you How to make DC Motor with cardboard without using glue gun step by step. things requir... a commutator, or collector with brushes connecting the armature with a DC power supply. The current flowing through the armature gives rise to the electromagnetic field that makes it rotate. As the armature rotates, the similar poles of the magnetic fields created around the stator and rotor repel each other and provide a unidirectional motion. What is DC Motor? A DC motor is an electric motor that runs on direct current power. In an electric motor, the operation is dependent upon simple electromagnetism. A current-carrying conductor generates a magnetic field, when this is then placed in an external magnetic field, it will encounter a force proportional to the current in the conductor and to the strength of the … Jun 08, 2020 · The stator is the DC Motor part that receives the supply. Find All Stator in Linquip. Rotor. The dynamic part of a DC motor is the rotor that creates the mechanical rotations of the unit. Find All Rotor in Linquip. Yoke. Another unit of the DC motor parts is the Yoke. A Yoke is a magnetic frame made of cast iron or sometimes steel, which works ...

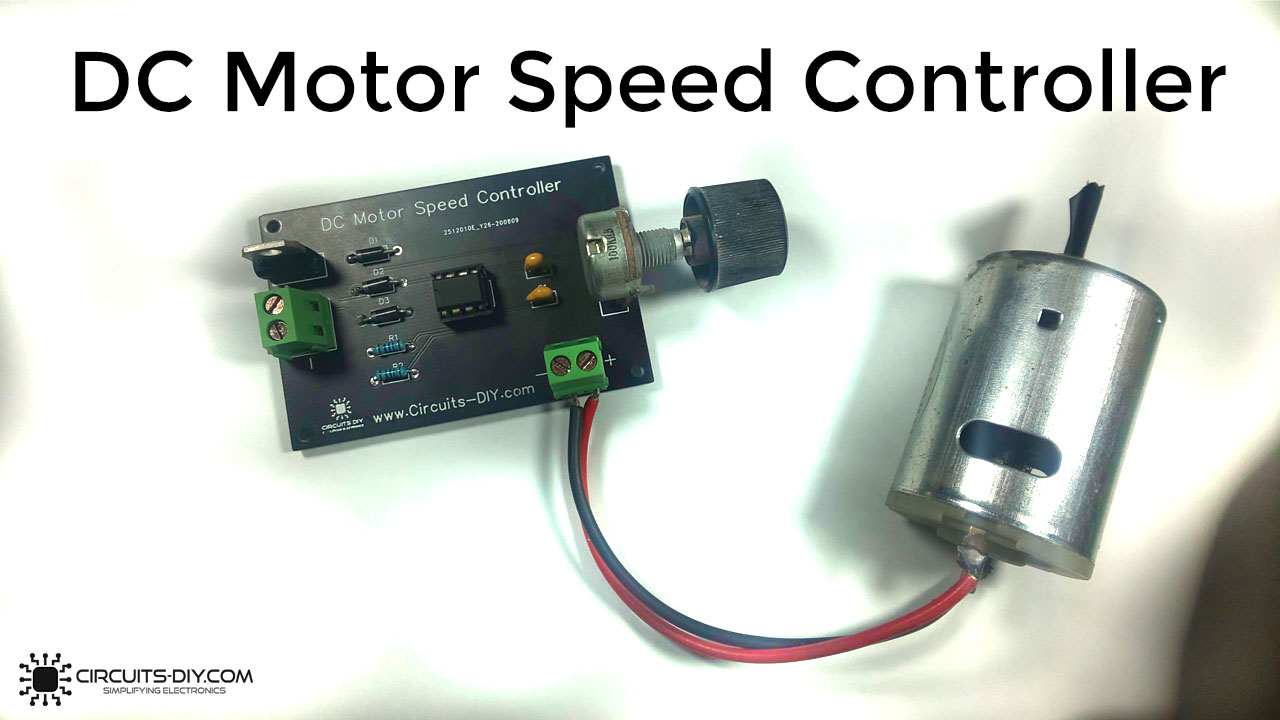

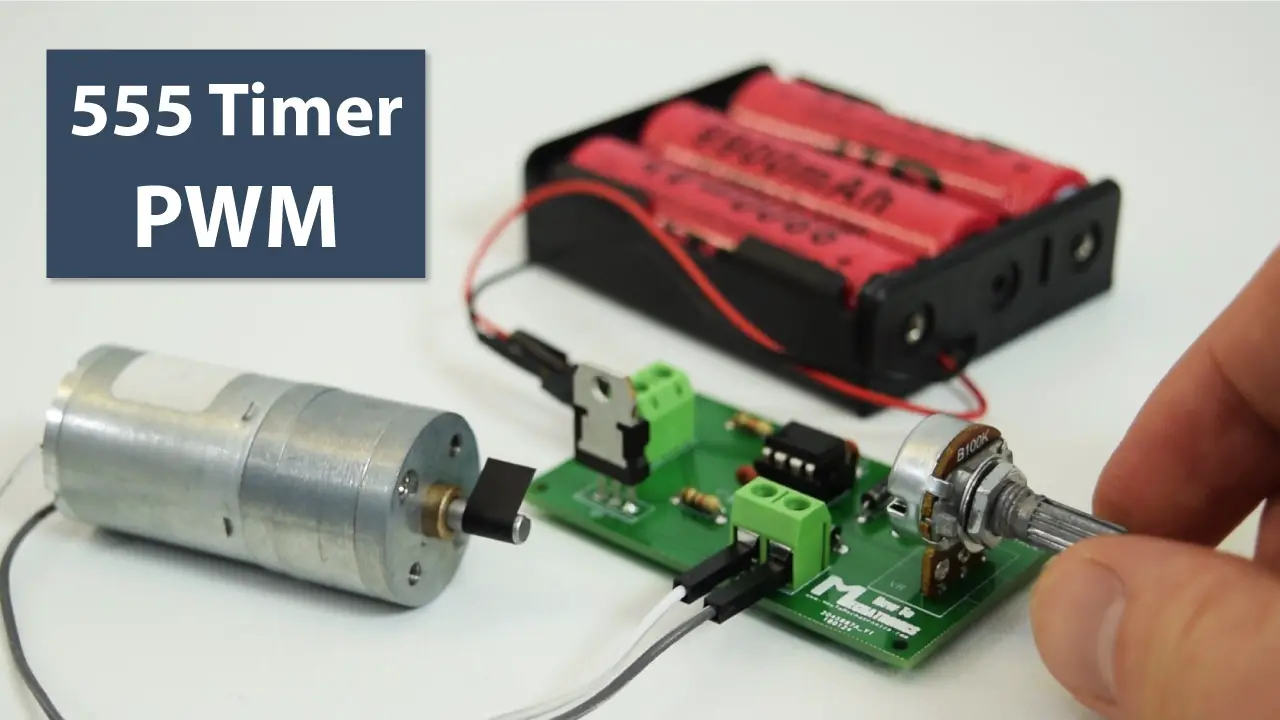

MM23001C-Q DC Motor Control MM23000C Series-QDT: Provides a quick disconnect terminal for quicker wiring and setup. The MM23001C-Q drive is a reliable and cost-effective solution for controlling your permanent magnet or shunt-wound DC motors in variable-speed applications. It uses SCRs to provide full-wave rectification of the AC line input. The DC motor will spin with different speeds according to the value (0 to 250) received via the serial port. Spin Direction Control. To control the direction of the spin of DC motor, without interchanging the leads, you can use a circuit called an H-Bridge. An H-bridge is an electronic circuit that can drive the motor in both directions. Make a DC Motor.: In this instructable I will show how to make a nice and functional DC motor. This motor can be used for demonstration purposes, as a class project or just to have it over your desk, it is really simple to make. Materials: -Slab of wood. -Magnet w… Learn how to control DC motor using Arduino, how to control DC motor speed and direction, how to connect DC motor to Arduino, how to program Arduino step-by-step. The detailed instruction, code, wiring diagram, video tutorial, line-by-line code explanation are provided to help you quickly get started with Arduino.

Oct 16, 2020 · Final thoughts. In this article, we went through all the important points about direct connection motors. Different DC motor types offer you various applications, and you need to choose the ones which fit the most with your requirements.. If you want to buy a direct connection motor, apart from the DC motor price, you need to go through all the characteristics we … A simple direct current (DC) motor is illustrated below. The motor features a permanent horseshoe magnet (called the stator because it’s fixed in place) and an turning coil of wire called an armature (or rotor, because it rotates). The armature, carrying current provided by the battery, is an electromagnet, because a current-carrying wire ... How To Make Juicer From PVC Pipe Using DC Motor At Home !!!Hello Friends !!! In this video i am gonna show you "How To Make Juicer From DC Motor Usi... Jan 17, 2020 · Unlike other motors, brushless DC motor has low no-load current making it suitable to run it at low or no load. Brushless DC motors can provide maximum torque continuously during rotation, while brushed DC motor can provide maximum torque at an only specific point of the rotation. For the same torque rating, the brushed motor will require a ...

The field winding of DC motor are made with field coils (copper wire) wound over the slots of the pole shoes in such a manner that when field current flows through it, then adjacent poles have opposite polarity are produced.

Jul 12, 2020 · DC drives are designed to shut down the motor in cases such as this. A DC motor is a motor all unto itself. Simple yet complicated. Proper maintenance of the brushes, brush springs, and commutator will always be needed. There is no better feeling than when the motor is installed and making money for your business.

The very simplest DC electric motors work by placing an electromagnet in a magnetic field made by a permanent magnet. The electromagnet is a piece of iron or steel with wire wound around it in one direction, and it turns the drive shaft which can spin freely along one axis.

A brushed DC electric motor is an internally commutated electric motor designed to be run from a direct current power source. Brushed motors were the first commercially important application of electric power to driving mechanical energy, and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings.

A DC motor field coil is a non-moving part on which winding is wound to produce a magnetic field. This electro-magnet has a cylindrical cavity between its poles. Commutator and Brushes Commutator The commutator of a DC motor is a cylindrical structure that is made of copper segments stacked together but insulated from each other using mica.

0 Response to "40 making a dc motor"

Post a Comment